Products

SKF

Reducing installation costs and time

Reducing installation costs and time

Mechatronics demonstrator This is the integration of mechanical and electronic engineering with associated proprietary control strategies for application in SKF’s products and processes.

Monitoring operating conditions as close to the contact area as possible gives greater accuracy for studying the performance of a system. In addition to temperature, speed, direction of rotation and vibration, loads can be monitored via sensors integrated into

Responding to the customers’ need for reducing installation costs and time and to increase the life of components, SKF develops products that make use of wireless technologies more efficiently.

Solving problems with advanced technology

Mechatronics is the science of bringing together mechanics and electronics into exciting new solutions. It is a rapidly advancing field that provides dramatic opportunity to solve old problems in efficient and environmentally-friendly ways. SKF has more than 400 engineers dedicated to this area.

Standard and custom solutions for the marine industry

By being at the forefront of this technology for many years, SKF has developed unique application knowledge in hardware and software. With expertise in actuators, bearings, sealing, lubrication, sensors and electronics , we have developed a number of standard and customized solutions. SKF offers a wide assortment of mechatronic products, fully suitable for marine environments and applications.

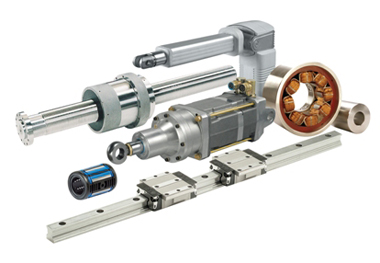

Mechatronics THK

THK's Mechatronics Division offers customized, turn-key solutions to your linear and rotary motion challenges. Mechatronics systems range from purely mechanical systems where the customer integrates the motion control to all-encompassing automation solutions where the customer receives a complete plug-and-play system out-of-the-box. Whether you require a one-of-a-kind multi-axis system, or a standard single-axis actuator, the highly-skilled Mechatronics engineering team will design the right solution according to your unique specifications.

Mechatronics units are built with THK's durable, high-quality LM guides, ball screws, and rotary motion components. In addition, THK's Caged Ball Technology delivers long service life and excellent high-speed performace while eliminating maintenance over a long period of time. As THK is the industry leader in linear motion, why not let us fulfill your automation needs? If you have a linear and/or rotary motion application you wish to pursue with THK, please contact your local THK sales representative to discuss your application in detail.

THK America, Inc. created their Mechatronics division to provide integrated standard THK actuators, customized actuators and a combination of THK linear motion products offering custom solutions for their customers' specific linear positioning applications.

THK engineers offer their expertise in designing and assembling precision positioning systems. This ensures that a system can be up and running, out of the box, with minimal set-up time. THK employs the benefits of its existing technologies and product features to develop Mechatronic products that meet varying application needs. To meet the most demanding requirements, THK's Mechatronics Division combines the exclusive, industry leading Caged Ballä technology with expertise in structural design and finite element analysis. For severe, corrosive environments THK offers a range of choices, from stainless steel components to chrome plating and other corrosion inhibiting techniques. To meet the need for precise, multi-axis positioning, high-resolution optical encoders, ground steel components, and other precision positioning equipment, techniques or materials may be included as part of a THK Mechatronics offering. And, for applications with extreme work envelope constraints, engineers can incorporate ultra-low profile LM guides, such as the RSR3WM (only 4.5mm high), with custom-made components optimized for strict space requirements.

THK's Mechatronics Division offers three levels of design: custom, modified standard and semi-standard. Custom designs begin with the submission of the customer's requirements pertinent to the application. The design engineers review the information, and upon their approval a "Quick Quote" and system specification sheet are generated within approximately 1 - 2 days of the request. When the customer approves the price and specifications, the design process begins. Finally, using the approved drawing, THK will develop, produce and test the final product. Modified standard and standard options entail the adaptation or integration of existing THK products. THK Mechatronics' standard "ME-Standard Options" can incorporate a standard THK GL or KR actuator into numerous applications, including dual carriages for high moment loads, multi-axis mounting brackets; or integrated, space-saving electromagnetic holding brakes.

Lastly, the Mechatronics product line of semi-standard products helps to bridge the gap that exists between standard THK product such as the KR actuator or HSR LM Guide, and custom designed products built for a specific application. For example, THK's LSA (Linear Servo Actuator) – a semi-standard product - makes linear motors a reality in non-traditional fields. The LSA's simple, straightforward operation and low cost is comparable to precision-ground ball screw actuator and servo packages that normally require separate purchases and assembly by the user.

Mechatronics Thomson

Often the ideal motion control solution for machine builders is not about finding the fastest, sturdiest, most accurate or even least expensive option. Rather, the ideal solution is theoptimal balance of performance, life and cost. Thomson is best positioned to help you most quickly configure the optimal solution for your application.

Thomson Airpax Mechatronics - a world leader in stepper motor technology - announces a bidirectional digital linear actuator (DLA) that provides high linear resolution as fine as .004 in. per pulse.

The new actuator is ideal for precise, measured control of fluids and gases in such applications as HVAC refrigerant flow control, and measurement and dispensing of medical fluids.

Called "Series K923," the DLA is a modified rotary stepper motor, with a rotor that includes an internally molded thread that mates to an externally threaded shaft (lead screw). Rotary motion is converted to linear movement, with the travel per step determined by the pitch of the lead screw and step angle of the motor.

Energizing the unit's coils (unipolar and bipolar) in proper sequence causes the threaded shaft to move out of, or back into the rotor in precise linear increments. When power is removed, the actuator shaft remains in position.

Weighing only 5.5 oz. (156 g.) with a maximum pull-in rate of 300 step/sec, the 12 models in the Series K923 feature a linear force up to 23 lbs.

Series K923 is rated with a maximum travel rate of 0.95" (24.1 mm) and a maximum linear force (2 phases energized) of 370 oz (103N).

Other key features include: - radial ball bearing construction for high efficiency - two voltage ratings - 5VDC and 12VDC - linear travel per step -- .001 in. (.025mm), .002 in. (.05 mm), .004 in (.10 mm) - power consumption - 10 watts - operating temperature range -- -20°C to 70°C - insulation resistance of 20 ohms

Thomson Airpax Mechatronics can provide electrical and mechanical changes tailored to individual application requirements.

For technical assistance, call a Thomson Airpax Mechatronics engineer at 1-888-554-6684, or 631-467- 8000, fax 631-981-0593, or E-mail: motorinfo@thomsonmail.com. Samples are available from stock. Unit pricing in 1-10 pieces is $75.00.

Thomson invented and manufactures a complete family of Ball Bushing* bearings, 60 Case* LinearRace* shafts, Thomson Saginaw* and IBL* ball screws; RoundRail*, Smart Rail* and ProfileRail* linear guides, systems and controls; Micron True Planetary* gearheads; Nyliner* engineered polymer bearings and FluoroNyliner* bushing bearings; precision bearing balls, and Thomson Airpax Mechatronics stepper motors, brushless DC motors, and digital linear actuators. All Thomson Industries manufacturing locations are ISO 9000 certified. Automotive facilities operate to QS-9000 standards. Thomson is a three-time General Motors Supplier of the Year, and a two-time ITT Gold Award Supplier.

Mechatronics tsubaki

Mechatronics tsubaki

Tsubaki E&M Co. was created to develop the new century's power transmission products, advancing machine technology accumulated in the 20th century. The power transmission field now calls for even more sophisticated and precision application products, and we plan to help meet those demands.

Our customers throughout the world rely upon our products and highly regard them as top in the industry.

Tsubaki E&M contributes to various areas, not only industry but also society, through our promotion of Mechatronics. We aim to be a company that contributes to "a more prosperous tomorrow for everyone".

Our precision ball screws and linear motion systems enable accurate and flexible linear motion in vertical and horizontal directions with the application of ultra-precision rotation. Computerization further enhances the applications of this technology that our company has developed. It is applied in the fields that require motion control with micron-level precision such as numerical controlled machine tools, semiconductor manufacturing equipment and industrial robots, largely contributing to the development of a wide range of industrial technology and precision machining technology.

Our ball screws also have an extremely high transmission efficiency of over 90%, demonstrating their effectiveness in conjunction with transmission systems such as motors. They are effectively used in an operation control system for injection molding machines and parabolic antennas, where powerful, accurate motion is required.

Furthermore, we have been researching various materials and developed products that can withstand extreme temperature shifts. They are used in airplane flaps, which require accuracy and a high level of safety that must be ensured in severe conditions.

In addition, our products are also used in the aircraft passenger boarding bridge, PAXWAY, at airports, a control system for chemical plant piping, a control system for control rods used in nuclear power plants and a pressure tube inspection system. The accurate motion they offer is greatly trusted in various fields.